Say Cheese for RFID

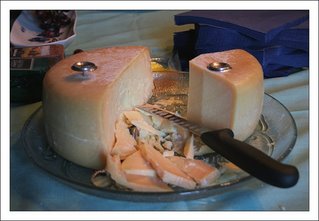

94-member cooperative of makers of Parmesan cheese in northern Italy successfully introduced RFID chips into their operation,which produces and handles several hundred thousand cheese wheels eachyear. Before you think this situation istrivial, look at the facts. The 30-kg(approximately 66-lb), tire-sized cheese wheels go through repeated aging cycles in climate-controlled warehouses for six to 36 months, andeach wheel is repeatedly graded duringthe process, by color, tap-sounding timbre,and even X-rays. Cheese-wheel prices range from less than $200 for an average one to more than $350 for atop-grade one. Making Parmesan is nota casual hobby; despite first appearances,it is a serious business.

The cheese makers in the area agreedto try embedding RFID chips into thecheese crust, because the previous method of branding the crust had shortcomings.Among them, the branded number gradually faded as the cheese was handled, and the branding didnothing to prevent the serious problemof counterfeit cheese wheels enteringthe supply chain. With RFID, the cheese makers can uniquely track and update the status of each cheesewheel and assure buyers of the cheese’sauthenticity.

Parasa

0 Comments:

Post a Comment

<< Home